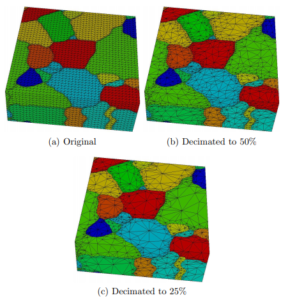

Multiple-Region Computational Geometry

Multiple-Region Computational Geometry

Suppose you had access to a 3D scanner or sets of CT or MRI scans and you wanted to visualize 3D models. Then the goal is to build a 3D model from pre-segmented points, where each point represents one region or material. We want the model to represent the shape accurately yet be as simple as possible. If we wanted to analyze the model using finite elements, then we also need a high-quality model that is water-tight and topologically correct. No overlaps or gaps would be allowed. Around 2005, most systems only considered one material or region, so our multiple-region computational geometry efforts were innovative at the time. Let us consider four major steps in a pipeline and then view some simple results.

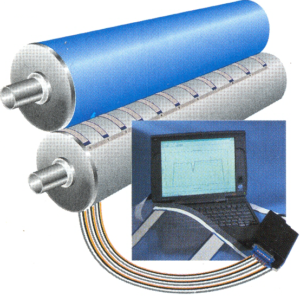

NipProfiler

I invented, patented, and brought to the field an electronic system for measuring the uniformity of presses for the paper industry. “Paper-thin” electronic sensors provide instant readouts of the contact uniformity from end to end of the rollers. This NipProfiler system won an international award in 1999 and has been used in most paper mills in the world. More details may be found in the following two papers and seven patents.

SMARTRoll

I invented, developed, and field tested the world’s first Smart Roll for the paper industry. This system measures the pressure profile all the way across the sheet in real time during production. The paper makers can see if one end is loaded more heavily than the other or if the ends are loaded more heavily than the center. More recently, I wrote a software module that estimates the potential energy savings for when we correct these profiles. These instrumented coatings should provide a huge step forward towards Industry 4.0 (IIoT) and future digital twins.

Rezolve

Rezolve

We built a simulation model for paper machines that used 400+ input variables. Starting from the most rewarding tuning parameters, we built a virtual control panel that empowered field engineers to optimize the paper making process. A yearly savings of 1 million US dollars per machine was common.

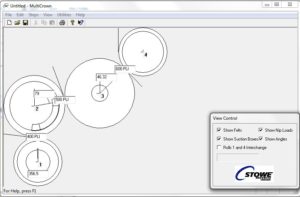

MultiCrown

The loaded rollers that press water out of the paper sheet during paper making can be arranged in clusters at various angles, such as the 4-roll press shown to the left. The rolls bend and deform and are “crowned” to obtain shapes that result in even contact pressure from one end of the roll to another. The optimum crown shape depends on all the loads, weights, suction pressures, felt tensions, and properties and dimensions of the metal roll shell. The MultiCrown program uses a simple CAD-style interface to input the roll dimensions and loads and then outputs a report that can be sent to a grinder for the optimum shape. Behind the scenes is a 3D finite element calculation engine.

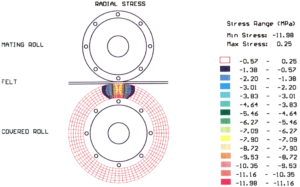

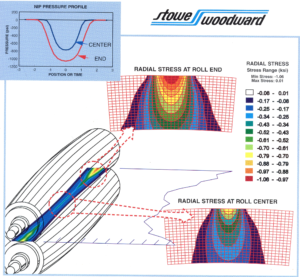

CrownCalc

Paper mill rolls don’t always have the proper shape that produces uniform loading profiles. For a given set of loads, there is one set of crown shapes that produces uniform loading. Quite often, the operators run at loads that differ from the designed load, so the pressure uniformity suffers. CrownCalc is a nonlinear contact finite element program that estimates the consequences of incorrect shapes or loads. For the undercrowned case shown on the left, the ends are loaded more heavily than the center, as shown by the red regions in the contour plot between the rolls. The roll cover (coating) stresses will also be different between the ends and center,as shown by the contour plots on the meshes or the 2D plot in the upper left hand corner. I wrote CrownCalc and published a paper as teaching tools to promote better uniformity during the paper making process.

NipCalc

NipCalc is a nonlinear thermoviscoelastic finite element code that predicts roll cover stress and temperature distributions for paper making conditions. A paper sheet rides on a press felt and passes through the loaded zone, called a nip, that is between two rolls, as shown in the figure on the left. This pressing operation is designed to remove water from the paper sheet. One or both of the rolls may be coated with an elastomer, such as rubber or polyurethane, that is up to 3 inches thick, although the coatings are generally just under an inch thick. The soft coatings provide more gentile lower pressures for the fragile sheet and also are more forgiving if there are local sheet thickness variations. The coatings are replaceable, so they can be less expensive than refreshing the roll body metal thickness. Since the elastomers have hysteresis, the cover temperatures can become excessive, so the program provides estimates for the temperature distributions. The program is used to design covers, confirm their safe application, and to estimate the shear stresses between layers to make sure there is no failure.

Calender Covers

Calender Covers

I had the honor or working with E.H.Jones in the field of supercalendering. One of the last steps in making a paper sheet is to calender it using very hard rolls to obtain glossier surfaces and to even out nonuniformities. We modeled the adverse effects of hot edges, general temperature variations, and incorrect crowning on the loading and bulk profiles. We also provided general advice for improving the sheet quality and for extending the life of the covered rolls. TAPPI chose our paper as one of the best in that decade.

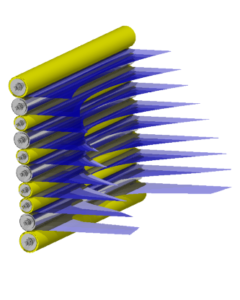

ViewRolls

ViewRolls

Communicating profile data is usually performed using 2D plots in Excel. I wanted to use a stronger visual approach and superimpose the profiles onto pictures of the rolls to make it clear that the rolls were being subjected to nonuniform loading and pressures. For the example shown on the left, the contact pressure distribution is shown by the colored “3D” contour plot embedded between the rolls. The loading distribution is projected out of the nip in the same direction as the sheet travel. I think this approach brings the nonuniform distributions to life. Graphics design firms have used some of my images as part of their marketing materials.